The Department of Mechatronics was started in the year 1996. Diploma in Mechatronics course was designed specially to cater to the needs of modern industries with the requirement of knowledge in Electronics, Mechanical and Automation Technologies. The Laboratories are continuously updated with the latest equipments to enable the students to have "Hands on Training" on state of the art equipment.

The mission of Department of Mechatronics is to provide fundamental knowledge in multi disciplinary fields of Engineering and instigate skills to develop innovative Mechatronics systems. Expose the students to latest technologies through continual improvement in the curriculum. Encourage Entrepreneurship and nurture quest for knowledge.

Department of Mechatronics aspires to be a pioneer in imparting technical knowledge and multi disciplinary skills in the young minds to develop and implement applied automation solutions in the industries and contribute to the development of the society.

| Name | Mrs.D.Sujatha, ME |

| Designation | Head of the Department |

| Teaching Experience | 13 Years |

| Industry Experience | 15 years |

| Area of Specialisation | Robotics, Industrial Automation, PLC and SCADA, Industrial Drives and Control. |

| Name | Mr.S.Thirumalairajan, ME |

| Designation | Lecturer |

| Teaching Experience | 14 years |

| Industry Experience | 1 year |

| Area of Specialisation | Embedded System Embedded Wireless Automation. |

| Name | Mr.R.Anguraj, M.E |

| Designation | Lecturer |

| Teaching Experience | 13 years |

| Industry Experience | 2 year |

| Area of Specialisation | Electrical Machines and Drives |

| Name | Ms.G.Hemalatha |

| Designation | Lecturer |

| Teaching Experience | 10 Years |

| Industry Experience | 3 Years |

| Area of Specialisation | Analog and Digital Electronics, Measurements and Instrumentation. |

| Name | Mr R Kailasam |

| Designation | Lecturer |

| Teaching Experience | 9 Years |

| Industry Experience | 1 Year |

| No of Journals | 6 |

| Area of Specialisation | Applied Mechanics, Manufacturing Technology, Design of Machine Elements, Thermal Engineering, Engineering Drawing |

| Name | Mr. S Prabhu M.E |

| Designation | Lecturer |

| Teaching Experience | 10 Years |

| Research Experience | 5 Years |

| Area of Specialisation | Advanced Manufacturing technology |

| Name | Mrs.R. Lavanya Rajan M.Tech., |

| Designation | Lecturer |

| Teaching Experience | 7 Years 4 Months |

| Area of Specialisation | Energy Engineering |

| Name | Ms.V.Geethanjali,B.E (ECE) |

| Designation | Instructor |

| Area of Specialisation | Analog and Digital Electronics |

|

PEO1 |

Apply the concepts of Mechatronics to design, develop and maintain automation systems in industries |

|

PEO2 |

Develop professional competency and attain skills for sustainable growth by exploring latest technologies in industrial automation |

|

PEO3 |

Lead a team or contribute as a part of the team with ethics and aptitude for continuous learning |

|

PSO1 |

Demonstrate technical competency in the Selection, Production, Testing and configuration of components in Mechatronic systems |

|

PSO2 |

Develop and implement Mechatronic systems by integrating Mechanical, Electronics and Control systems |

|

PO1 |

Basic and Discipline specific knowledge: Apply knowledge of basic mathematics, science and engineering fundamentals and engineering specialization to solve the engineering problems. |

|

PO2 |

Problem analysis: Identify and analyse well-defined engineering problems using codified standard methods. |

|

PO3 |

Design/ development of solutions: Design solutions for well-defined technical problems and assist with the design of systems components or processes to meet specified needs. |

|

PO4 |

Engineering Tools, Experimentation and Testing: Apply modern engineering tools and appropriate technique to conduct standard tests and measurements. |

|

PO5 |

Engineering practices for society, sustainability and environment: Apply appropriate technology in context of society, sustainability, environment and ethical practices. |

|

PO6 |

Project Management: Use engineering management principles individually, as a team member or a leader to manage projects and effectively communicate about well-defined engineering activities. |

|

PO7 |

Life-long learning: Ability to analyse individual needs and engage in updating in the context of technological changes. |

| Theory | Practicals |

|---|---|

| PHYSICS | PHYSICS LABORATORY |

| CHEMISTRY | CHEMISTRY LABORATORY |

| BASIC MATHEMATICS | C PROGRAMMING LABORATORY |

| ALGEBRA AND ANALYTICAL GEOMETRY | |

| PRACTICUM: Engineering Graphics I | AUDIT COURSE: Integrated Learning Experience I |

| Theory | Practicals |

|---|---|

| CALCULUS AND ITS APPLICATIONS | APPLIED PHYSICS LABORATORY |

| APPLIED PHYSICS | INDUSTRIAL CHEMISTRY LABORATORY |

| CHEMISTRY OF ENGINEERING MATERIALS | BASIC ENGINEERING PRACTICE |

| TECHNICAL ENGLISH | |

| PRACTICUM: Engineering Graphics II | AUDIT COURSE: Integrated Learning Experience II |

| Theory | Practicals |

|---|---|

| ELECTRONIC DEVICES AND CIRCUITS | ELECTRONIC DEVICES AND CIRCUITS |

| APPLIED MECHANICS | ANALOG AND DIGITAL ELECTRONICS |

| ANALOG AND DIGITAL ELECTRONICS | MACHINE SHOP LABORATORY |

| MANUFACTURING TECHNOLOGY | ADVANCED COMMUNICATION SKILLS |

| PRACTICUM: Computer Aided Design | AUDIT COURSE: Integrated Learning Experience III |

| Theory | Practicals |

|---|---|

| PROBABILITY AND STATISTICS | SENSORS AND INSTRUMENTATION LABORATORY |

| SENSORS AND INSTRUMENTATION | ELECTRICAL MACHINES LABORATORY |

| ELECTRICAL MACHINES AND DRIVES | FLUID AUTOMATION LABORATORY |

| HYDRAULICS AND PNEUMATICS | TECHNICAL 3D MODELLING LABORATORY |

| TECHNICAL COMMUNICATION LABORATORY | |

| PRACTICUM: Basic Python Programming | AUDIT COURSE: Integrated Learning Experience IV |

| Theory | Practicals |

|---|---|

| MICROPROCESSOR & MICROCONTROLLER | MICROPROCESSOR & MICROCONTROLLER LABORATORY |

| ROBOTICS | EMBEDDED SYSTEM LABORATORY |

| ELECTIVE THEORY – I | MINI PROJECT |

| PRACTICUM: Programmable Logic Control | AUDIT COURSE: Integrated Learning Experience V |

| Theory | Practicals |

|---|---|

| ARTIFICIAL INTELLIGENCE IN AUTOMATION | CNC LABORATORY |

| CNC TECHNOLOGY | ROBOTICS LABORATORY |

| ELECTIVE THEORY – II | PROJECT WORK |

| PRACTICUM: Industrial Automation | AUDIT COURSE: Integrated Learning Experience VI |

| Theory |

|---|

| AUTOMOTIVE MECHATRONICS |

| CAD/CAM AND FMS |

| KINEMATICS AND DYNAMICS |

| MACHINE VISION IN AUTOMATION |

| MOBILE ROBOTICS |

| EMBEDDED SYSTEM PROGRAMMING |

| Theory | Practicals |

|---|---|

| ENGINEERING MATHEMATICS I | PHYSICS LABORATORY |

| PHYSICS | CHEMISTRY LABORATORY |

| CHEMISTRY | FITTING SHEET METAL & WIRING WORKSHOP |

| ENGLISH | INPLANT TRAINING |

| ENGINEERING GRAPHICS I | PHYSICAL EDUCATION – I |

| Theory | Practicals |

|---|---|

| ENGINEERING MATHEMATICS II | ENGINEERING PHYSICS LABORATORY |

| CALCULUS AND ITS APPLICATIONS | CHEMISTRY OF ENGINEERING MATERIALS LABORATORY |

| ENGINEERING PHYSICS | FOUNDRY AND WELDING WORKSHOP |

| CHEMISTRY OF ENGINEERING MATERIALS | COMMUNICATION ENGLISH LABORATORY |

| ENGINEERING GRAPHICS II | PHYSICAL EDUCATION – II |

| Theory | Practicals |

|---|---|

| PROBABILITY AND STATISTICS | CAD LABORATORY |

| APPLIED MECHANICS | STRENGTH OF MATERIALS LABORATORY |

| BASIC ELECTRICAL AND ELECTRONICS ENGINEERING | ELECTRICAL CIRCUITS AND ELECTRONIC DEVICES LABORATORY |

| MANUFACTURING TECHNOLOGY | WORKSHOP – LATHE AND SPECIAL MACHINES |

| PROGRAMMING IN C & PYTHON LABORATORY |

| Theory | Practicals |

|---|---|

| ANALOG AND DIGITAL ELECTRONICS | ANALOGAND DIGITAL ELECTRONICS LABORATORY |

| SENSORS AND INTERFACING | SENSORS AND INTERFACING LABORATORY |

| ELECTRICAL MACHINES AND DRIVES | CIRCUIT SIMULATION LABORATORY |

| HYDRAULICS AND PNEUMATICS | FLUID AUTOMATION LABORATORY |

| TECHNICAL COMMUNICATION LABORATORY | |

| INTERNSHIP* |

| Theory | Practicals |

|---|---|

| MICROCONTROLLER | MICROCONTROLLER LABORATORY |

| ROBOTICS | EMBEDDED SYSTEM PROGRAMMING LABORATORY |

| ELECTIVE THEORY I | PLC LABORATORY |

| ELECTRICAL MACHINES LABORATORY | |

| MINI PROJECT AND ENTREPRENEURSHIP |

| Theory | Practicals |

|---|---|

| INDUSTRIAL AUTOMATION | INDUSTRIAL AUTOMATION LABORATORY |

| CNC TECHNOLOGY | CNC LABORATORY |

| ELECTIVE THEORY II | TECHNICAL 3D MODELLING LABORATORY |

| ROBOTICS LABORATORY | |

| PROJECT WORK AND VIVA VOCE |

| Theory |

|---|

| CAD/CAM AND FMS |

| ARTIFICIAL INTELLIGENCE AND ITS APPLICATION |

| MACHINE VISION IN AUTOMATION |

| AUTOMOTIVE MECHATRONICS |

| EMBEDDED SYSTEM PROGRAMMING |

*Internship will be arranged for 4 weeks during the vacation at the end of 4th semester

This Centre was set up in association with SIEMENS AUTOMATION limited in 2000 and is equipped with modern automation systems like PLC, CNC SYSTEMS, INDUSTRIAL DRIVES, HMI panels to train the students in the field of automation.

This lab is equipped with Electronic components, Digital Trainer kits, Sensor Kits, Micro processors and Micro controllers for teaching basic Electronic courses.

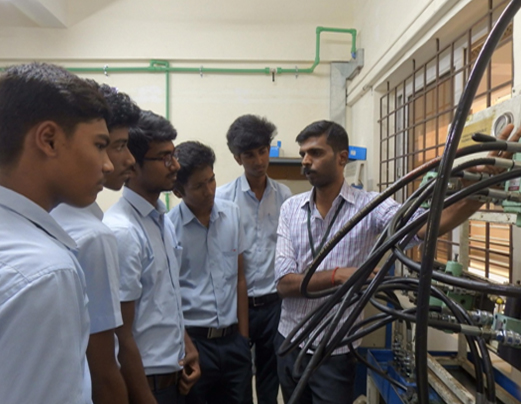

This Lab, setup in Collaboration with M/s. Yuken India Ltd, provides students with hands on experience in oil hydraulics and pneumatics. The facilities include manually operated hydraulic simulation kit, Electro hydraulic simulation kit, PLC based hydraulic simulation kit.

This Lab, sponsored by DOTE, provides students with hands on experience to program and work with robot kits. The facilities include robotic kits and simulation software.

| S.No | Event Nature | Event Title | Date | Image | |

| 1 | One day Training Program | Low-Cost Automation | 27.03.2025 | Mr. G. Ragesh Kumar, Product Manager – Low Cost Automation, IGUS® (India) Pvt. Ltd., Bangalore |  |

| 2 | Guest Lecture | Mindful journey VUCA World | 10.08.2024 | Mr.V. Sivaganesh, Head-Supply Chain and Business Process Management, FANUC India Pvt. Ltd. |  |

| 3 | Guest Lecture | Role of Augmented reality in Industry 4.0 | 20.03.2024 | Mr.M.KamalPrasathBalaji, CEO-Dot World Technologies |  |

| 4 | Guest Lecture | Advancements and Applications of Pneumatic Automation | 06.02.2024 | Mr.R.Sasikumar, Asst. Manager, Didactic Initiative Janatics India Pvt,Ltd, Coimbatore. |  |

| 5 | One day Seminar | Smart Factories Transforming Manufacturing through Automation and AI | 09.12.2023 | Mr.JanradhanTyagi, General Manager-Sales, Schneider Electric India Private Limited, Coimbatore |  |

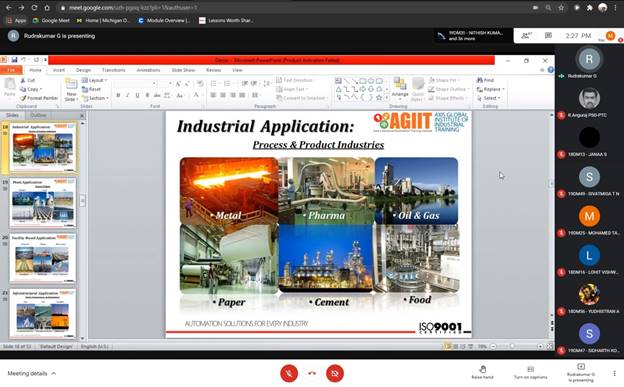

| 6 | Guest Lecture | Facts and Future of Industrial Automation | 06.10.2023 | Mr.Kanakaraj and Mr.Boobalan, Application Engineers, Spectrum Control System, Coimbatore- 641001 |  |

| 7 | Guest Lecture | Emerging Technologies in Industrial Automation | 09.08.2023 | Mr K Dinesh kumar, Managing Director M/S RD Automation |  |

| 8 | Guest Lecture | Role of Mechatronics in Condition Based Monitoring | 12.04.2023 | Mr V S Mani Shastha, Chief Business Development officer, Dyna4cast Technologies Pvt Ltd |  |

| 9 | Guest Lecture | Industry 4.0 | 24.03.2023 | Mr R Bhuvaneshwaran, Service engineer, SIEMENS Ltd |  |

| 10 | Webniar | Process Automation Simulation using Automation Studio | 11.11.2022 | Mr Madhujit Nandkumar kulkarni, Mr Akshay Vedpathak |  |

| 11 | Guest Lecture | Startup Entrepreneurship | 07.10.2022 | Mr G Jayaprakash, CEO, Mahesh Engineering Industries, Coimbatore |  |

| 12 | Guest Lecture | Industrial Internet of Things (IIOT) | 21.04.2022 | Mr S Gopala Krishnan, Manufacturing Executio system –IT Analyst, Schlumberger India Pvt, Ltd, Coimbatore |  |

| 13 | Guest Lecture | Employability skills | 14.05.2022 |  |

|

| 14 | Guest Lecture | Industrial IoT | 21.04.2022 |  |

|

| 15 | Guest Lecture | The Journey of an Entrepreneur | 26.11.2021 |  |

|

| 16 | Guest Lecture | The autonomous way to Industry 4.0 | 12.11.2021 |  |

|

| 17 | Guest Lecture | Python Programming | 09.04.2021 |  |

|

| 18 | Guest Lecture | Future Scope Industrial Robotics & Automation | 13.03.2021 |  |

|

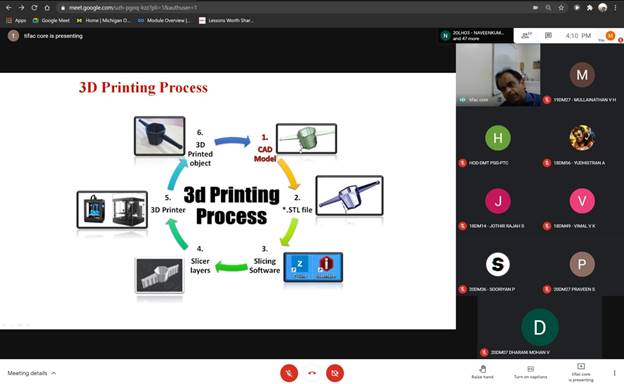

| 19 | Guest Lecture | Latest Trends in 3D Printing Technology | 23.02.2021 |  |

|

| 20 | Guest Lecture | Mechatronics in Automobile | 29.10.2020 |  |

|

| 21 | Guest Lecture | Industrial Automation | 14.08.2019 |  |

|

| 22 | Guest Lecture | Entrepreneurship | 03.07.2019 |  |

|

| 23 | Valedictory Function cum Guest Lecture | Current Industry Scenario | 07.03.2019 |  |

|

| 24 | Guest Lecture | Lean Startup | 07.09.2018 |  |

| Faculty | Title | Image |

|---|---|---|

| Mr.S.Thirumalairajan | Teacher of Year 2019 |  |

| CNC Operator – Turning | CNC Operator – Turning.pdf |

| S.No | Training Program | Date | Image |

|---|---|---|---|

| 1. | A two-day Faculty Development Programme (FDP) on "Intelligent Systems and Immersive Technologiesfor Industry 4.0 | 21.02.2025 and 22.02.2025 |  |

| S.No | Collaborating Organization | Scope of MoU | Image |

|---|---|---|---|

| 1. | B.J. ELECTRONICS PVT LTD |  |

|

| 2. | RD AUTOMATION |  |

|

| 3. | M/s.Synetics Automation Soluions (P) Ltd., Coimbatore | To provide an opportunity for the students to get exposed to current industrial scenario from this leading manufacturer of CNC autoloaders, food dispensing systems and Robotic machine tending solutions,etc. |  |

| 4. | M/s.Mahesh Engineering Industries , Coimbatore | To provide internship opportunity and Alma matter. |  |

| 5. | DoT World Technologies , Coimbatore | To provide internship opportunity |  |

Batch 2024-2025

| S.No | Details of the Activity | Date | Organized by | No. of students participated |

|---|---|---|---|---|

| 1. | SREC Inter polytechnic Innovation Championship 2025 | 30.01.2025 | SREC Collaborative Innovation Center, Sri Ramakrishna Engineering College, Coimbatore. | R.Gowtham, V.Sanjaikumar, S.Viswaharshan , S.M.Sanjay |

| 2. | Online Course on “Introduction to Management” | Feb 2024 | Great Learning Academy | DwaragaPrasath S (21DM12) |

| 3. | Online Course on “Introduction to Information Security” | Feb 2024 | Great Learning Academy | DwaragaPrasath S (21DM12) |

| 4. | Online Course on “Introduction to Cyber Security” | Feb 2024 | Great Learning Academy | DwaragaPrasath S (21DM12) |

| 5. | Preliminary round of YESIST12 | 2024 | IEEE student branch of Kumaraguru | Mitran S (21DM27) |

| 6. | Two Days Workshop on Astrophysics | 27.01.2024 and 28.01.2024 | Ethical EdufabricaPvt.Ltd. | BharathiSenthilkumar (22DM10) |

| 7. | Product Design Workshop | 27.01.2024 and 28.01.2024 | Petrichor’24 Techno Cultural Fest of IIT Palakkad | Adharsh S (22DM03) |

| 8. | Technical Event | 15.03.2024 | “Dhruva 2024” at Karpagam College of Engineering | Govind.P.Suchit (23LH03) |

| 9. | Technical Event | 15.03.2024 | “Dhruva 2024” at Karpagam College of Engineering | Govind.P.Suchit (23LH03) , Sri HariPrasath V , Nithish Krishna S (22DM33), Rithish R (22DM40) |

| 10. | Completed the Diploma in Business Administration | - | CPD certified | Thiyaneshwaran S (22DM49) |

| 11. | Speaker at AIR element and session titled ‘Research Review on Co2 Reducion through Air Element by YginArme” | 14.09.2024 | IGEN ENVIRONTHON-2024 (World Recorded Marathon) | BharathiSenthilkumar (22DM10) |

| 12. | Apsara Conference 2024 AI Journey with Al Journey with Alibaba Cloud | 28.11.2024 | Alibaba cloud certification | Thiyaneshwaran S (22DM49) |

| 13. | Online course Artificial Intelligence Beginners Guide : What is AI? | 22.10.2024 | Skillup | Thiyaneshwaran S (22DM49) |

| 14. | Human Centered Design Crash Course | 26.11.2024 | Federal Ministry for Economic Cooperation and Development | Thiyaneshwaran S (22DM49) |

| 15. | HP Life online Course Data Science & Analytics | 26.11.2024 | HP Foundation | Thiyaneshwaran S (22DM49) |

| 16. | CS205: Building with Artificial Intelligence | 27.11.2024 | Saylor.org Academy | Thiyaneshwaran S (22DM49) |

| 17. | An Introduction to Electronics | Nov 2024 | The open university | Thiyaneshwaran S (22DM49) |

| 18. | The agnirva space internship problem | 16.12.2024 | agnirva | BharathiSenthilkumar (22DM10) |

| 19. | HP Life online Course AI for Beginners | 22.12.2024 | HP Foundation | BharathiSenthilkumar (22DM10) |

| 20. | International Tai chi conference – ITCC 2024 Tai Chi for Energy | 20.09.2024 | Dr Paul Lam | Sivachalapathy V |

| S.No. | Roll Number | Name of the student | Name and place of the event | Date of participation | National level/State level |

|---|---|---|---|---|---|

| 1. | 22DM52 | 31.01.2025 and 1.02.2025 | Sankara PTC | R.Vivinyaa III year DMT | National Level Technical SympasiumSantekfest, 2k25 |

| 2. | 22DM37 | 31.01.2025 and 1.02.2025 | Sankara PTC | D.Rakshitha III year DMT | National Level Technical SympasiumSantekfest, 2k25 |

| 3. | 22DM03 | 31.01.2025 and 1.02.2025 | Sankara PTC | S.Adharsh III year DMT | National Level Technical SympasiumSantekfest, 2k25 |

| 4. | 22DM10 | 31.01.2025 and 1.02.2025 | Sankara PTC | BharathiSenthilkumar | National Level Technical SympasiumSantekfest, 2k25 |

| S.No | Details of the Activity | Date | Organized by | No. of students participated |

|---|---|---|---|---|

| 1. | State Republic Day Parade Camp -2025, held at Vellore Institute of Technology, Chennai. | 17th to 26th January 2025 | Government of Tamil Nadu Youth Welfare and Sports Development Department Tamil Nadu state NSS Cell Directorate of Collegiate Education | T.V.Kanish II year DMT |

| 2. | EK Bharat Shreshtha Bharat Camp – II | 18.01.2025 to 29.01.2025 | NCC Group HQ, Tiruchirappalli at NCC Training Area, Idayapatti (Madurai) | R.S.Naresh |

| 3. | NCC-Annual Training Camp | 03.06.2024 to 12.06.2024 | 4 Tamilnadu Battalion NCC,Coimbatore | V.Aswaddhaman, R.S.Naresh |

| 4. | Most people performing viparitaKaraniyogasna simultaneously the world Record “most people performing viparitakaraniyogasana simultaneously” | 16.01.2024 | Mahamaharishi Foundation MahayogamZenskar Healing Martial Arts at Madurai | S.Atitya Ram III year DMT |

| 5. | Secured First place in IPPA Divisional Athletic Meet for Men 2023-24 1st -110 m hurdles | 21.02.2024 | Government of Tamil Nadu, Directorate of Technical Education Inter Polytechnic Athletic Association Tamil Nadu-Puducherry | Narendhirakumar. A (22DM30) |

| 6. | Secured First place in IPPA Divisional Athletic Meet for Men 2023-24 1st -400 m hurdles | 22.02.2024 | Government of Tamil Nadu, Directorate of Technical Education Inter Polytechnic Athletic Association Tamil Nadu-Puducherry | Narendhirakumar. A (22DM30) |

| 7. | Secured First Place in IPAA divisional Badminton Tournament for women | 05.02.2024 | PSG Polytechnic College | Vivinyaa R (22DM52) |

| 8. | Secured Second Place in IPAA divisional volley ball Tournament for women | 07.02.2024 | Hindusthan polytechnic Coimbatore | Vivinyaa R (22DM52) |

| 9. | NSS South Zone pre-republic day parade camp-2024 | 5th to 14th Nov 2024 | Regional Directorate of NSS, Bangalore at Davangere University | T.V.Kanish II year DMT |

| 10. | Directorate level Centralized Selection of NSS Volunters | 26.09.2024 | Auspices of NSS Cell, Directorate of Technical Education, Chennai | T.V.Kanish II year DMT |

| S.No. | Roll Number | Name of the student | Title of the paper | Name of the Journal/Conference | ISSN/ISBN No. | Date of publication |

|---|---|---|---|---|---|---|

| 1. | 22DM05 | Adstan Patrick Albert | PC(Personal Computer) Components-Predictive Maintenance | International Journal of Scientific Research in Engineering & Management | 2582-3930 | January,2025 |

| 2. | 22DM49 | Thiyaneshwaran S | PC(Personal Computer) Components-Predictive Maintenance | International Journal of Scientific Research in Engineering & Management | 2582-3930 | January,2025 |

| 3. | 22DM29 | Nantha Kumar N | PC(Personal Computer) Components-Predictive Maintenance | International Journal of Scientific Research in Engineering & Management | 2582-3930 | January,2025 |